-

[수상소식] 2025년도 한국세라믹학회 추계학술대회 KCerS 우수포스터상 수상

[수상소식] 2025년도 한국세라믹학회 추계학술대회 KCerS 우수포스터상 수상2025년도 한국세라믹학회 추계학술대회 KCerS 우수포스터상을 김창중 석사과정이 수상하였습니다. 축하드립니다.

-

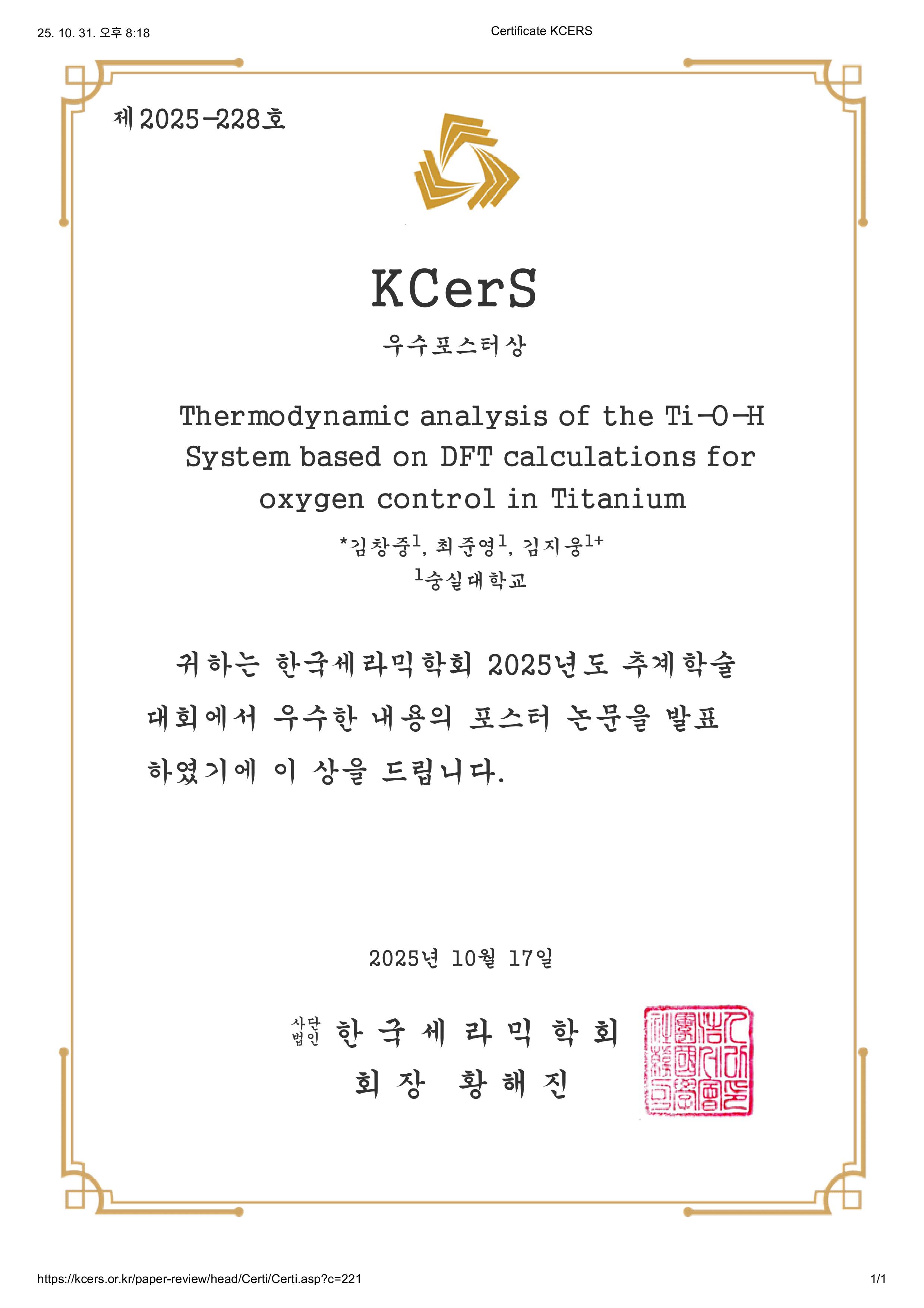

[논문게재] High-temperature stability in Ti-based MAX phases: vacancy effects on mechanical prop…

[논문게재] High-temperature stability in Ti-based MAX phases: vacancy effects on mechanical prop…Author: H.Kim†, H.Son†, Y.Jeong, J.Kim*Title: High-temperature stability in Ti-based MAX phases: vacancy effects on mechanical properties Journal: Journal of Korean Ceramic SocietyYear: 2025Impact factor: 3.8Abstract:Tin+1AlCn MAX phases are of interest due to their high-temperature mechanical properties. In this study, we investigated their structural and mechanical properties up to 2000 K using molecular dynamics (MD) tensile simulations and density functional theory (DFT) calculations, focusing on the effect of vacancies. The presence of up to 12.5% Al vacancies reduced the vertical Young’s modulus by only 12.59% and left the UTS almost unchanged, demonstrating considerable mechanical robustness. In contrast, the same concentration of Ti vacancies degraded the Young’s modulus by 40.7% at 2000 K. Electron localization function (ELF) analysis confirmed that the mechanical properties are dominated by strong Ti–C covalent bonds, which are not weakened by Al vacancies. In comparison to B1-type TiC, whose Young’s modulus decreases by ~ 32% at 2000 K, Tin+1AlCn retains over 88% of its room-temperature vertical Young’s modulus. This work provides a theoretical basis for considering Tin+1AlCn MAX phases as potential high-temperature structural materials.

-

[취업소식] 이진용 석사 LG에너지솔루션 합격

[취업소식] 이진용 석사 LG에너지솔루션 합격연구실에서 석사과정을 마친 이진용 석사가 LG에너지솔루션 CPO 직무에 합격하였습니다. 축하드립니다.

-

2025년 11월 19일 ~ 11월 21일 KJ-ceramics 학회 참석

2025년 11월 19일 ~ 11월 21일 KJ-ceramics 학회 참석제주 오리엔탈 호텔에서 열린 The 39th International Korea-Japan Seminar on Ceramics에 김효경, 경수아, 김창중, 이권열 학생이 참석하여 구두 발표 및 포스터 발표를 진행하였습니다.

-

2025년 11월 17일 ~ 11월 19일 ATSC 2025 학회 참석

2025년 11월 17일 ~ 11월 19일 ATSC 2025 학회 참석2025년 11월 17일부터 2025년 11월 19일까지 부산 BPEX에서 열린 14th ATSC(Asian Thermal Spray Conference & EXPO) 학회에 참석하였습니다.

-

2025년 11월 15일 관악산 등반

2025년 11월 15일 관악산 등반2025년 11월 15일 토요일에 연구실 인원이 모두 모여 관악산 연주대 등산을 하였습니다. 모든 인원 다친 곳 없이 포기하지 않고 끝까지 등산하고 즐거운 시간을 보냈습니다.'체력이 국력이다'라는 말이 있듯, 대학원생에게는 체력이 좋아야 학위과정을 끝까지 마칠 수 있는 힘이 생긴다고 생각합니다.또한, 등산과 마찬가지로 연구실 생활 중 힘들 때, 지칠 때가 있어도 곁에 있는 연구실 동료들을 함께 끌어주고 밀어주며 다같이 정상에 도달했으면 좋겠습니다.CMD 화이팅~~!!!