BOARD

News

|

[논문게재] Combined experimental and computational investigation of precipitation behaviour and mechanical properties in a novel Cu–Ni–Si–Co alloy: effect of solution treatment temperature 관리자 │ 2024-10-04 HIT 24010 |

|---|

|

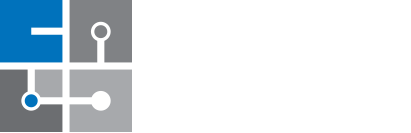

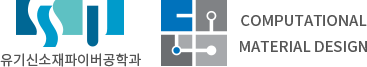

Title: Combined experimental and computational investigation of precipitation behaviour and mechanical properties in a novel Cu–Ni–Si–Co alloy: effect of solution treatment temperature Journal: Materials Technology Year: 2024 Impact factor: 2.9 Abstract: Cu alloys are extensively utilized in electronics for heat exchangers, electrical conductors, automotive connectors, and electrical contacts. To meet the demands of miniaturization, these alloys must exhibit enhanced strength and electrical conductivity. We investigated the microstructural and precipitation properties of the Cu–Ni–Si–Co alloy at the solution treatment temperature (1,050°C). We subjected the alloy to cold rolling and ageing. The secondary-phase particles dissolved completely at higher temperatures, increasing the concentrations of the Ni, Si, and Co solutes within the Cu matrix. This enhanced supersaturation facilitated higher precipitation during ageing, resulting in fine (Ni,Co)2Si precipitates with a number density of 12.3 × 1010 cm-2. The alloy was strengthened by the Orowan mechanism and exhibited good electrical conductivity. Moreover, nanoscale (Ni,Co)2Si precipitates were formed. We achieved the highest hardness of 251 hV and an electrical conductivity (EC) of 51% International Annealed Copper Standard (IACS).

|

| 이전글 | [논문게재] Ab initio calculations of Nb-based MAX phases as bond coats for t... |

|---|---|

| 다음글 | [논문게재] Active-type piezoelectric smart textiles with antifouling perform... |

![Figure 2. TEM images of the Cu–1.3Ni–0.6Si–1.0Co alloy. (a) and (b) BF images and (c) HR–TEM image and corresponding FFT image of fine precipitates along [001]Cu at 1,050°C. (d) BF image, (e) DF image, and (f) HR–TEM image and FFT image of coarse precipitates along [001]Cu at 950°C. (g) BF image, (h) DF image, and (i) HR–TEM image and FFT image of fine precipitates along [001]Cu at 1,050°C.](https://www.tandfonline.com/cms/asset/31b5e5ae-753d-4f71-9f6b-46ef74489fb2/ymte_a_2408132_f0002_oc.jpg)